It seems like you’re looking for information about CNC machining parts made from aluminum and stainless steel. Here’s a breakdown:

Aluminum CNC Machining Parts:

Aluminum is a widely used material in CNC machining due to its excellent properties such as lightweight, corrosion resistance, and ease of machining. Here are some common types of aluminum parts that are CNC machined:

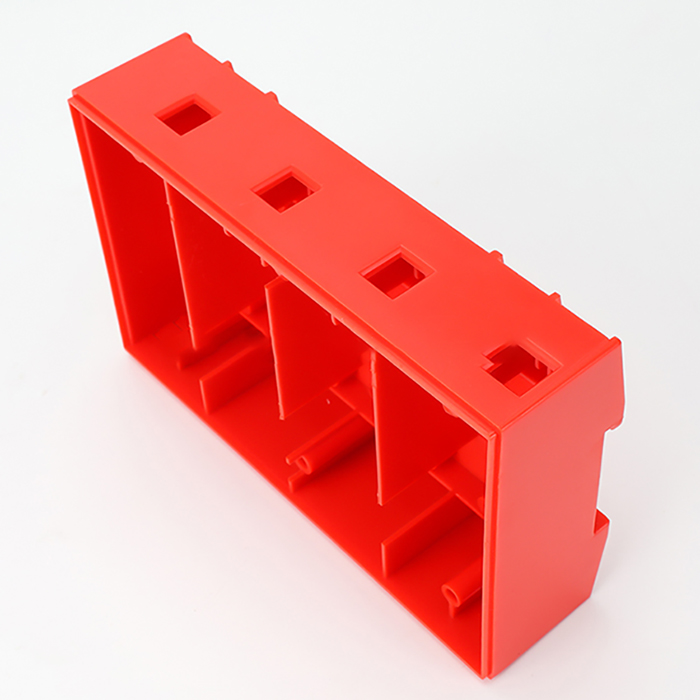

1.Enclosures and Housings: Used in electronics, automotive, and aerospace industries for protecting components.

2.Heat Sinks: Essential for thermal management in electronics and other heat-sensitive applications.

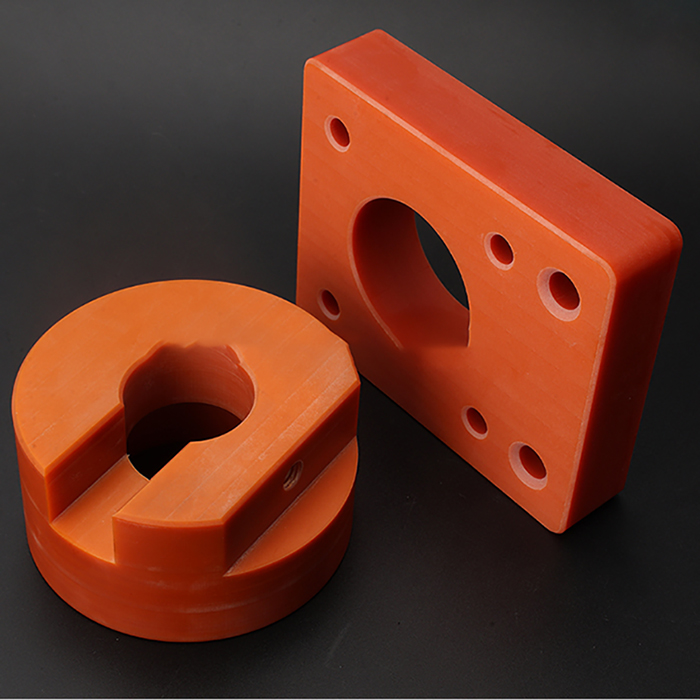

3.Brackets and Mounts: Provide structural support and attachment points in various equipment.

4.Prototypes and Custom Components: CNC machining allows for precise fabrication of prototypes and customized parts.

Stainless Steel CNC Parts:

Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for parts that require robust mechanical properties. Some examples include:

5.Shafts and Pins: Used in machinery and automotive applications for transmitting torque and securing components.

6.Fasteners: Bolts, nuts, and screws made from stainless steel are essential for joining parts in assemblies.

7.Valve Components: Stainless steel’s corrosion resistance makes it ideal for valves and fittings in industrial applications.

8.Medical and Surgical Instruments: Precision parts for medical equipment due to sterilization requirements and durability.

Choosing a Manufacturer:

When selecting a manufacturer for CNC machined parts, consider the following factors:

9.Expertise and Experience: Look for a manufacturer with a track record of producing high-quality parts in aluminum and stainless steel.

10.Capabilities: Ensure they have the CNC machining capabilities to handle your specific part requirements, including size, complexity, and volume.

11.Quality Control: Check if they have quality certifications (e.g., ISO 9001) and processes in place to ensure consistent part quality.

12.Materials Knowledge: Verify their expertise in working with aluminum and stainless steel grades suitable for your application.

13.Additional Services: Consider if they offer services such as finishing (e.g., anodizing, polishing), assembly, and prototyping.

Finding Suppliers:

14.Online Directories: Websites like ThomasNet, Alibaba, or industry-specific directories list CNC machining service providers.

15.Referrals: Ask colleagues or industry contacts for recommendations based on their experiences.

16.RFQ (Request for Quote): Contact multiple suppliers to compare pricing, lead times, and capabilities.

By carefully evaluating your needs and the capabilities of potential suppliers, you can find a reliable partner for producing aluminum and stainless steel CNC machined parts tailored to your specifications.