Aluminum Extrusion Services

In the past 5 years, more and more customers asked us to help them make the aluminum or plastic extrusion. So we developed some supplier and built a long term relationship with them on extrusion prototype making and low volume production. Our rapid aluminum extrusions process offers the prototype in as little as 3 weeks, and the main advantage of our rapid extrusion process is the ability to create prototype extrusions with very complex cross sections.

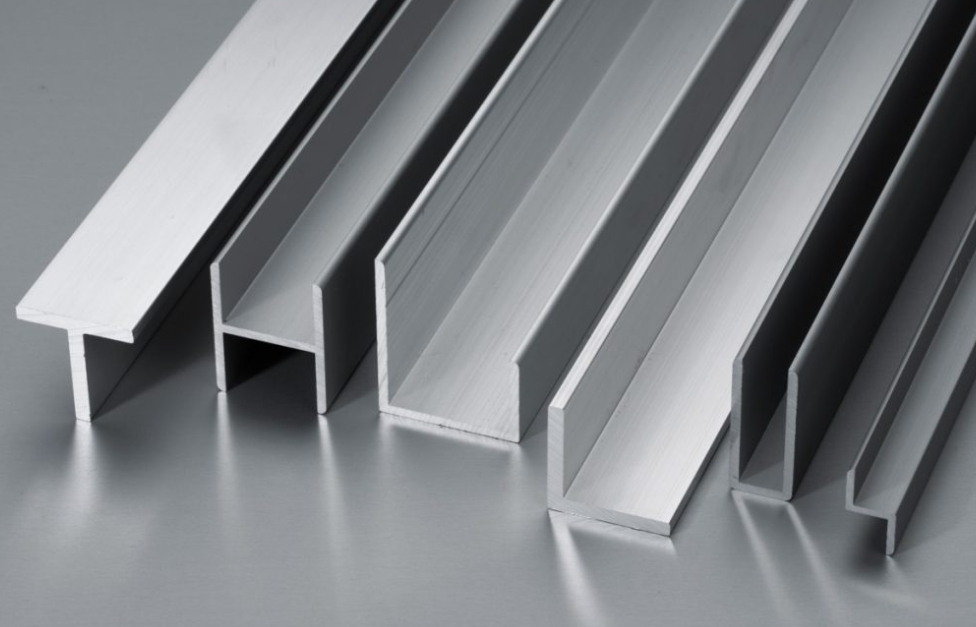

What is Aluminum Extrusion

Aluminum extrusion is the process of forming the aluminum into the desired shape and geometry. Aluminum extrusion is known for its high strength, light weight, and good electrical conductivity, making them an excellent choice for a variety of end-use applications, such as enclosures and radiators. And it is most cost effective for mass production runs of metal parts due to the significant reduction in unit price.

The flexibility of aluminium let it to quickly be cast as well as machined. In addition, it has a decent amount of rigidity and thickness of steel. It will ensure that every resulting product provides stability and strength. It is possible when it is alloyed with any other metals. If you need aluminum extrusion services, please do not hesitate to contact us.

Benefits of Aluminum Extrusion

Here are the benefits of aluminum extrusion.

- Strong:Aluminum extrusions can be made as strong as needed for most applications and, due to the nature of the extrusion process, the strength can be concentrated where it is really needed by including varying wall thicknesses and internal reinforcement in the profile design. Cold-weather applications are particularly well served by extrusions, as aluminum becomes stronger as temperatures fall.

- Corrosion resistant:Aluminum extrusions offer excellent corrosion resistance. They do not rust, and the aluminum surface is protected by its own naturally occurring oxide file, a protection that can be enhanced by anodizing or other finishing processes.

- Quick-to-market:Tooling for aluminum extrusion is relatively inexpensive with generally short lead times, facilitating prototype development, testing, and product launch.

- Lightweight:Aluminum is about 1/3 the weight of iron, steel, copper or brass, making aluminum extrusions easier to handle, less expensive to ship, and an attractive material for use in applications where weight reduction is a priority such as transportation and other applications involving moving part.

- High in strength-to-weight material:Aluminum extrusions’ unique combination of high strength and low weight makes them ideal for applications like aerospace, truck trailer and bridges where load carrying is a key performance.

If you have a need for aluminum extrusion, please feel free to contact us. We will get back to you as soon as possible.

Aluminum Extrusion Materials

The aluminum alloy materials we usually used are 6061 and 6063. which contain high levels of magnesium and silicone. Both are highly corrosion resistant.

The following is a comparison of the two materials.

| Aluminum Alloy material | Description | Characteristic |

| 6061 | 6061 is a multi-functional alloy, which can be heat treated to 6061-T6 and other tempering. Magnesium and silicon are the main alloy elements that can endow materials with high structural strength, toughness and weldability. | High toughness, Good weldability, Corrosion resistance, |

| 6063 | 6063-T5 is a very economical heat treatable alloy with a smaller grain structure than 6061 alloys. 6063 is more common for extrusions than 6061. It can form parts with thin walls and responds well to finishing processes, making it suitable for decorative applications. | High strength Corrosion resistance Easily extruded Economical |

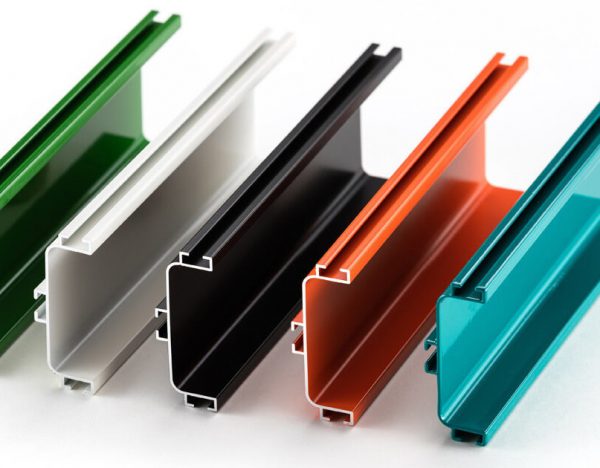

Available Aluminum Extrusion Finishes

- Mechanical Finishing:Aluminum can be buffed, polished, blasted, sanded, or ground. This is usuallydone to improve the surface quality of the extrusion in order to prepare it for further cosmetic finishes.

- Anodizing:Anodizing is one of the most common surface treatments used for aluminum surface treatment. It can improve the corrosion resistance, wear resistance and durability of part.

- Painting:Painting is an effective method to change the color and surface appearance of aluminum extrusions. Whether the part requires a matte, gloss or textured finish.

- Powder Coating:Offering a limitless choice of colors and repeatability, powder coating is one of the most wide spread methods of aluminium finishing.

- Silk-screenPrinting:By making use of screen printing techniques, an extruded profile’s surface can have both color and natural anodizing finishes. One of the simplest ways to add text and logos to aluminum extrusions, silk-screen printing is cheaper than machine-based finishing procedures.

- Passivation:It is a method to change the metal surface into a state that is not easy to be oxidized, thus delaying the corrosion rate of metal.

Aluminum Extrusion FAQs

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!