Rapid Prototyping Services

Over the past 20 years, HAOSTAMPING technical team has been focusing on the research, design and making rapid prototype tooling, constantly summarizing the experience, and formulated a set of special standards for prototype mold production to achieve the balance of quality, speed and cost for the maximum benefit of customers, and reduce the cost to the maximum extent and achieve win-win situation with customers. These years, we have helped lots of startups and established brands manufacture prototypes and products that compete favorably in the global market.

HAOSTAMPING offers a variety of rapid manufacturing processes that can be used to create prototypes quickly and affordably. Like CNC machining, Injection molding, Sheet Metal Fabrication, and Urethane Casting.

What is Rapid Prototyping?

Rapid prototyping is a kind of fast and economical tooling which makes with modern-high speed ,accuracy machining equipment, simplified and reliable tooling design option and effective machining procedure to match the part design specifications in terms of precision and quality in a very short delivery time. Prototypes are often used to test the feasibility of the design.

Rapid Prototyping Materials

All of our usual metals and plastic materials offerings are available for rapid prototype.

Insert Materials

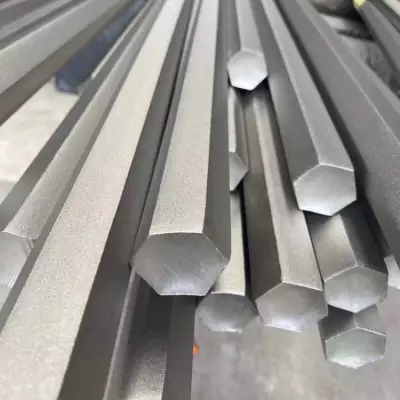

The following materials will be selected for rapid processing and cost reduction.

- Hard Aluminum7075.

Aluminum 7075 can be processed quickly, and it is one of the strongest alloys commercially available, which has good corrosion resistance and oxidation resistance. The hardness is about 90~120HB that can reach above 350HV after hard anodizing. Therefore, aluminum 7075 is the most common material for rapid prototype tooling, and the tooling life can range from 500 to 5000 shots. - Carbon structural steel, 1050 (S50C)

This is the most economical steel for rapid prototype tooling and also easy to machine. But the tooling life of Aluminum 7075 should be longer.

The Process of Rapid Prototyping

Design for

Manufacturability Analysis

Provide a detail DFM (design for manufacturability analysis) to show all the detail information, including parting lines, gate position and size, ejector position, wall thickness, surface finishing, tolerances and potential sink mark, gate mark warpage etc.

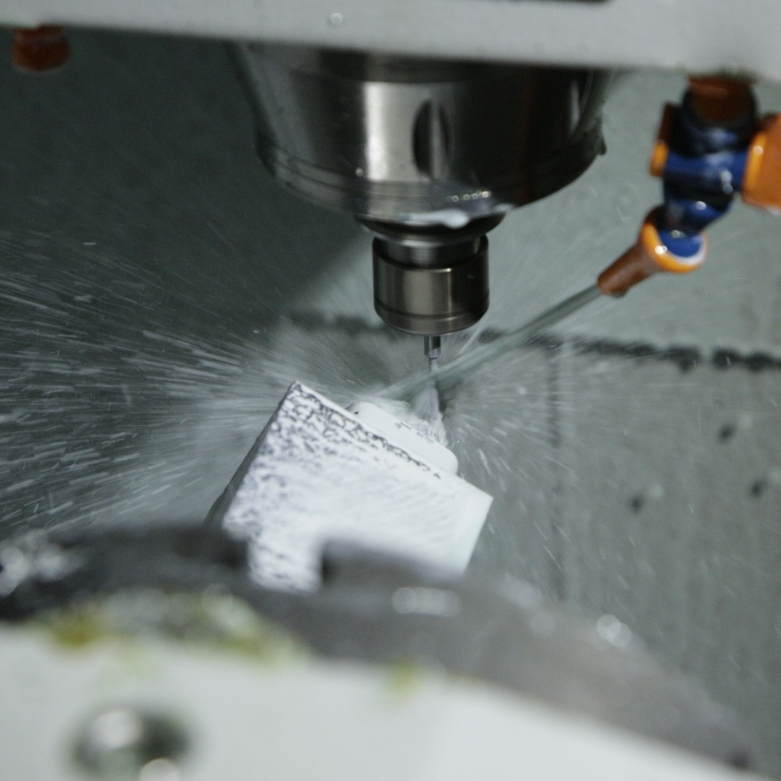

Tooling Machining& Fitting

After DFM approval ,cutting steel and machining with different machines, like Drilling, CNC, EDM, Wire cutting. Finally, molding master collects all components together for mold fitting and polishing, and prepares the tooling before mold trial.

Mold Trials and Quality Inspection

The molding Master prepares and dries the materials to make the machine reach the required temperature, and the test mold is filled from 10% to 110%. Finally, the project engineer checks and sends five completed photos to the QC department for quality and dimension inspection.

Benefits of Rapid Prototyping

Using rapid prototyping in the product development stage can help customers fully understand the feasibility of the design, assess whether the product meets current market demand, and make adjustments before the product is launched into the market. Now, more and more customers recognize and use rapid prototyping. Because of there are many advantages of rapid prototyping.

1、Reducing Product Development and Costs

Rapid prototyping allows your idea turn into reality quickly and efficiently. Time-saving early in the development stage help bring you one step closer to a final product and reduce the cost that yields a return on your investment.

2、Testing the Functions of Product

The prototype reflects exactly how your product looks and operates. Testing and retesting provide opportunities to fine-tune your ideas and turn them into the winning designs that are most likely to succeed. Does it offer a sound user experience? Does it achieve your goals? At this point, you can uncover the features that need a little more work and identify potential areas for expansion.

3、Evaluating and Identifying Product for Potential Safety and/or Compliance Issues

From appearance to function, this stage is where you can get to the root of any risk factors involved in your design. A large number of materials are used in the rapid prototyping process, making it easy to find the ideal combination that ensures your final product achieves your goals.

4、Speed to market

Rapid prototyping and accurate tooling help improve productivity and ultimately provide a faster market introduction than other methods.

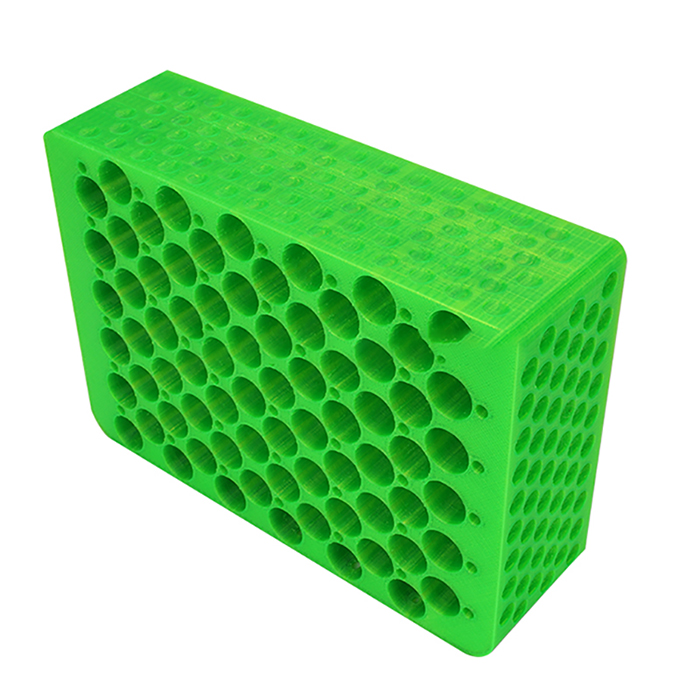

5、Compatibility with a Wide Range of Materials

CNC machining is employed to machine a wide range of materials including several types of plastic and metals. This makes it an ideal choice for rapid prototyping across industries.

Rapid Prototyping FAQs

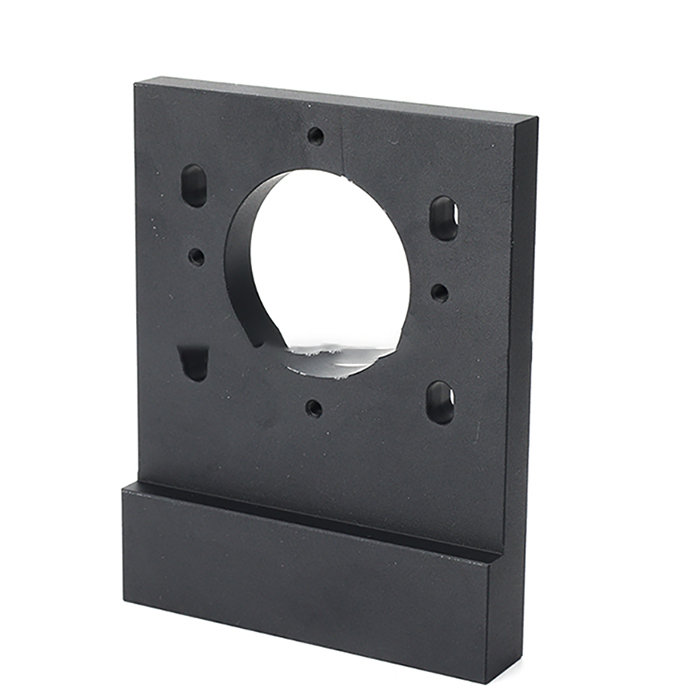

Case of Rapid Prototype

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!