CNC Machining Services

HAOSTAMPING offers customers with varieties of precision CNC machining services, including CNC milling, CNC turning, EDM, wire cutting and surface grinding. With the advanced 3-axis, 4-axis and 5-axis CNC machining center and an experienced team, we can make any custom design, simple or complex. If you have any CNC parts need to manufacturing.

What is CNC Machining?

Rapid CNC machining is a fast and economical method for manufacturing a few precision prototype from plastic and metal materials. It is widely used in the development and design of new products. Of course, it is also a common method to make volume manufacturing for some parts with limited molding. Such as high-quality mobile phone case, laptop case, lampshades, etc. But the cost is slightly higher than extrusion, pressure die casting and other processes.

Different Types of CNC Machines

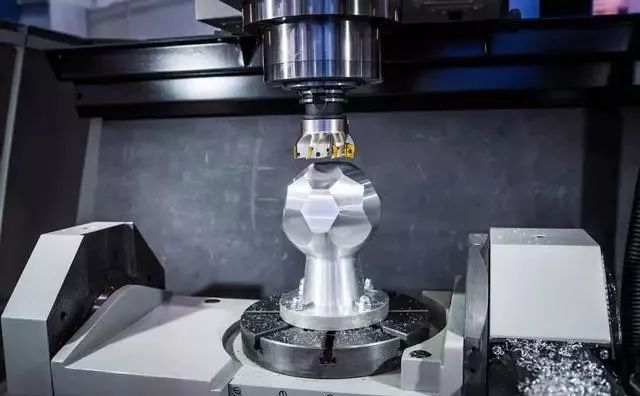

CNC Milling

CNC milling is just one of the CNC machining processes available. Milling is a particular form of precision CNC machining. Milling uses a cutter that removes material by moving into the work-piece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability.

CNC Turning

CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning work-piece. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the work-piece, which is usually stationary. Because CNC turning involves rotating the work-piece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes.

The tooling that is used with a CNC lathe machine is mounted to a turret. This component is programmed to make certain movements and remove material from raw materials until the desired 3D model is formed.

Like CNC milling, CNC turning can be used for the rapid manufacture of either prototypes or end-use parts.

Tolerances

Tolerances for feature size:

- Standard +/- .005

- Minimum +/- .002 for metal and +/- .003 for plastic

Tolerances for hole diameter:

- Standard +/- .005

- Minimum +/- .001 for metal and +/- .002 for plastic

Tolerances for Flatness, Run Out, Cylindricity, Perpendicularity and other Geometry:

- Standard +/- .005

- Minimum +/- .002 for metal and +/- .003 for plastic

The above tolerances will not apply when machining a weldment, or a plate below 1/4″ thick at a length above 20″ or 1/8″ thickness at a length exceeding 10″ long. In that case the tolerances need to be reviewed by the HAOSTAMPING team.

Available Materials

We work with a wide range of plastic and metal materials, including magnesium, mild and stainless steel, aluminum, brass and titanium as well as rigid engineering grade plastic resins. These materials are parts of our standard stock and can be sourced from reliable suppliers that have been thoroughly reviewed and approved by us for immediate access. In addition, we can also provide specialty materials, such as super hard alloys – just talk to our engineers to learn how we can meet your needs.

Most importantly, in order to ensure that your parts meet all regulatory requirements, we have an incoming materials inspection lab where we use sophisticated analytic testing instruments using Raman spectroscopy to confirm the exact chemical and physical properties of all raw materials. We leave nothing to chance for your peace of mind.

- ABS

- Brass

- LDPE

- Nylon

- Ultem

- Acrylic

- Carbon Steel Alloys

- Magnesium

- Noryl

- Radel

- Acetal/Delrin

- Copper

- Nylon

- Polycarbonate

- Stainless Steel

- Aluminum

- CPVC

- Nylon

- PEEK

- Titanium

Available CNC Machining Finishes

- As machined (standard)

- Bead Blasting

- Engraving

- Anodizing

- Polishing

- Painting

- Plating

- Passivation

- Powder coating

- Screen printing

- Heat treating

- Custom

Benefits of CNC Machining

The benefits of Rapid CNC Machining are numerous. Once a tool path is created and a machine is programmed, it can run a part 1 time, or 100,000 times. CNC machines are built for precision manufacturing and repeatability which makes them cost-efficient and highly scalable. CNC machines can also work with a variety of materials from basic aluminum and plastic to more exotic materials like titanium,making them the ideal machine for almost any job. That’s why Rapid CNC Machining is one of the most popular methods of making plastic and metal components.

Rapid CNC Machining is great to meet a range of your product development needs. Here are some of the benefits of precision machining:

- Wide range of materials

- Economicaland Fast turnaround

- Ability to hold tight tolerances

- Scalability and repeatability

- Scalable volumes from one to 100,000

- Parts machined directly from 3D CAD models

- Standard delivery time of 1-2 weeks based on order

- Shorter lead time (2-5 business days) available per open capacity

Why Choose CNC Machining for rapid prototype?

CNC machining is a technique that makes use of computer and compatible software throughout the machining process. The machining paths and production processes are programmed before the actual manufacturing to ensure desirable results. The following features of this technique make it a suitable choice for rapid prototyping.

Quick Production

CNC is a quick machining process. It complements the concept of rapid prototype production. CNC machining is an automated process once the CNC program is set and CAD design is set into the machine. Multiple prototypes can be manufactured simultaneously and effortlessly. Flexible Tooling: CNC machining offers flexible tooling. The tools can be changed during the production cycle without interrupting or stopping the production. Different tools like single-point cutting tools, drilling tools, tapping tools, milling tools, etc can be used in CNC machining.

Flexible Tooling

CNC machining offers flexible tooling. The tools can be changed during the production cycle without interrupting or stopping the production. Different tools like single-point cutting tools, drilling tools, tapping tools, milling tools, etc can be used in CNC machining.

Dimensional Accuracy

CNC machining is a precision machining process. It can achieve the smallest tolerance. Therefore, the expected dimensional accuracy can be easily achieved by using this process. Also, CNC manufactured components often require no surface treatments like polishing, therefore the dimensional accuracy remains unchanged.

Scope for Modification

The CNC production cycle can be modified based on design. One feature can be created using different techniques. For example, grooves can be formed by using grooving or depth cutting. CNC machining offers the flexibility of choosing the machining process during programming.

Compatibility with a Wide Range of Materials

CNC machining is employed to machine a wide range of materials including several types of plastic and metals. This makes it an ideal choice for rapid prototyping across industries.

CNC Machining FAQs

Cases of CNC Machining

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!