Structural foam core materials and structural foam molding companies are integral to various industries due to their lightweight yet strong properties. Here’s an overview of both aspects:

Structural Foam Core Materials:

- Types of Core Materials:

1.Polyurethane (PU) Foam: Known for its versatility and ability to provide good strength-to-weight ratio.

2.Polystyrene (PS) Foam: Offers excellent insulation properties and is commonly used in construction and packaging.

3.Polyethylene (PE) Foam: Lightweight and resistant to moisture, used in applications requiring cushioning and protection.

- Properties and Applications:

4.Strength and Weight: Structural foam cores are lightweight but provide structural integrity, making them suitable for applications where weight reduction is critical without sacrificing strength.

5.Insulation: Many foam cores offer thermal insulation properties, making them ideal for applications in construction and refrigeration.

6.Impact Resistance: They can absorb impact energy, making them useful in packaging and automotive applications.

- Industries Using Structural Foam Cores:

7.Construction: Used in panels for walls, floors, and roofs to enhance insulation and structural integrity.

8.Transportation: Applied in automotive and aerospace industries for lightweight components.

9.Marine: Used in boat building for hulls and decks due to their buoyancy and durability.

Structural Foam Molding Companies:

- Manufacturing Processes:

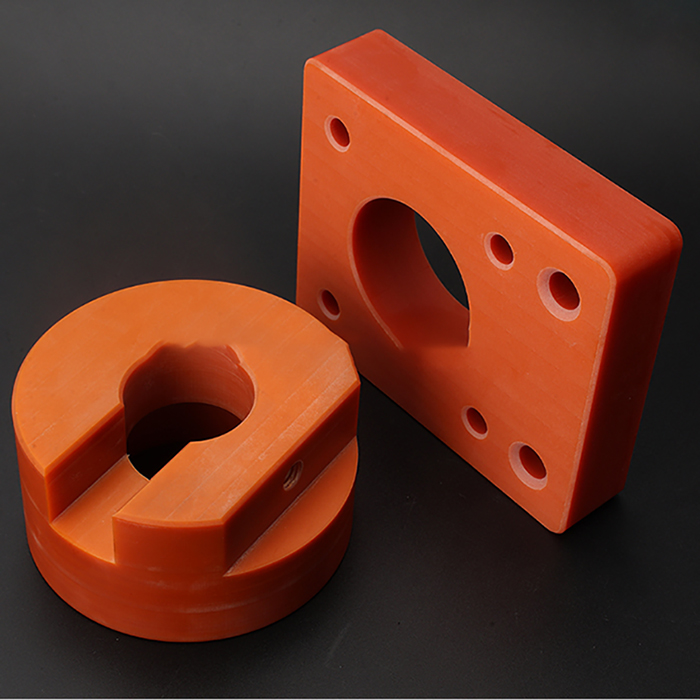

10.Injection Molding: Most common for producing structural foam parts. Involves injecting molten material into a mold cavity under high pressure.

11.Rotational Molding: Suitable for large, hollow parts. The mold is rotated while heated resin is applied, ensuring uniform coverage.

12.Compression Molding: Uses heat and pressure to mold composite materials.

- Services and Capabilities:

13.Custom Molding: Companies offer custom molding services to meet specific client requirements, including part design, prototyping, and production.

14.Material Expertise: Proficiency in working with various foam core materials and composite materials to achieve desired mechanical properties.

15.Quality Control: Ensures parts meet industry standards for strength, dimensional accuracy, and durability.

- Examples of Structural Foam Molding Companies:

16.Valiant TMS: Specializes in automotive structural foam molding for lightweight vehicle components.

17.Molded Foam Technologies: Provides structural foam molding services for a range of industries including construction and transportation.

18.IAC Group: Offers structural foam molding solutions for automotive interiors and other applications.

In summary, structural foam core materials and the companies specializing in structural foam molding play crucial roles in modern manufacturing. They contribute to lightweight, durable, and efficient solutions across industries ranging from construction and transportation to consumer goods and aerospace. These materials and processes continue to evolve, offering new possibilities for lightweight, strong, and cost-effective products.