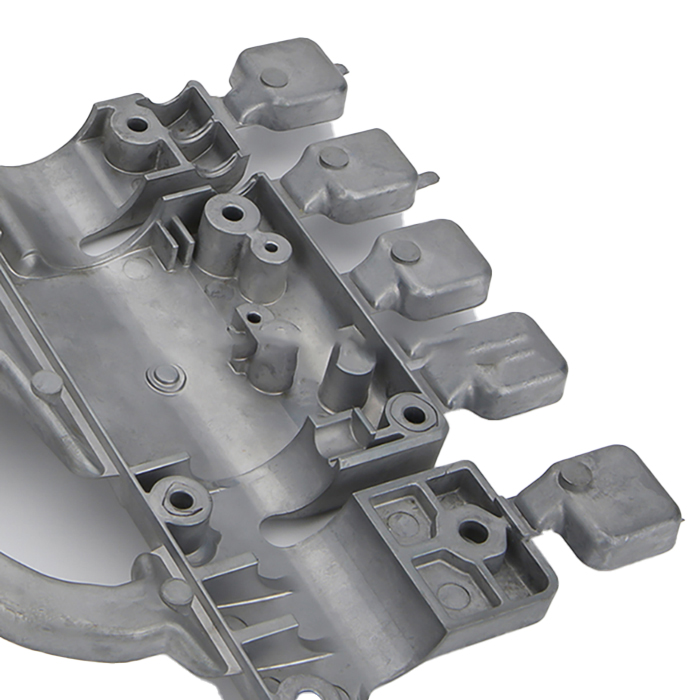

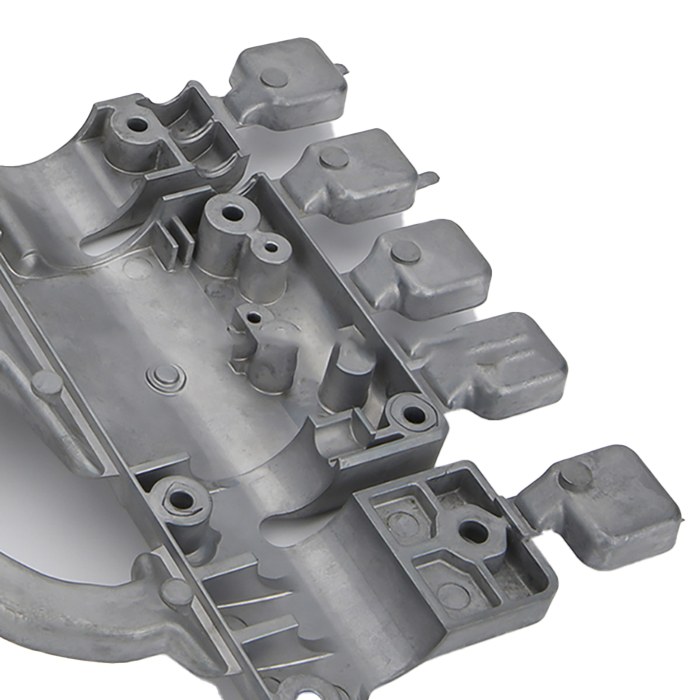

Pressure Die Casting Services

HAOSTAMPING also provide pressure die casting service for our customers. With years of expertise in this field , our pressure die casting service ensures consistent excellence whether you need a small quantity or several hundred castings. Pressure die casting is great for the automotive industry as well as electric, aerospace, kitchenware and hardware applications.

Contact us for more information about our pressure die casting services.

What is pressure die casting

Pressure die casting, also known as die casting, is a technique used to produce complex-shaped parts made from non-ferrous metals such as aluminum, zinc, and magnesium. It involves injecting molten metal into a reusable steel mold, known as a die, at high pressure and speed. The die is specifically designed to shape the metal into the desired form, with intricate details and excellent surface finish.

At HAOSTAMPING, we offer a range of core services in pressure die casting to meet our customers’ diverse needs.

Die Casting Materials

In fact, different metals can be used for casting. The materials you choose may depend on the cost, weight, and performance of parts. Here are some materials often used in HAOSTAMPING.

Aluminum Die Casting

Aluminum alloys are the most widely used in die casting.Aluminum alloy has light weight, high temperature resistance and good corrosion resistance, which is very useful in manufacturing various products. And we usually use the following aluminum alloys to make the parts:

- A356.0

- A360.0

- A380.0

- A383.0 (ADC12)

- A413.0

Zinc Die Casting

Zinc is a versatile high-performance material.Its strength and stiffness allow it to produce parts with thinner walls and highly detailed features and maintain tight tolerances.

Magnesium Die Casting

Magnesium is another material commonly used in die casting. It is most suitable for complex castings because of its high tolerance and enhanced corrosion resistance.

Available Die Casting Finishes

The Benefits of Pressure Die Casting

- Ability to produce high volumes of identical metal components, with high levels of accuracy

- Cost-effective solution for the mass production of castings

- Molten metal solidifies in a matter of seconds, or even milliseconds, for faster production

- Can produce thousands or even millions of components before needing to be replaced.

- Ideal for a wide range of applications

- Great for highly complex and precise components

- Suited to long production runs or where large volumes are needed

- Close dimensional control and good surface finish

- Castings with thin walls, and so lighter in weight

- Most pressure die casting can be discreetly electroplated without any further processing

Pressure Die Casting FAQs

Case of Pressure Die Casting

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!