Inhoudsopgave

Benefits of Using Plastic Injection Molding for Pet Toy Manufacturing

Plastic injection molding is a widely used manufacturing process in the production of various products, including pet toys. This method involves melting plastic pellets and injecting them into a mold to create a specific shape. The process is highly efficient and cost-effective, making it an ideal choice for pet toy manufacturers looking to mass-produce their products.

One of the key benefits of using plastic injection molding for pet toy manufacturing is the ability to create complex shapes and designs with precision. The molds used in this process can be customized to produce intricate details and textures that would be difficult or impossible to achieve with other manufacturing methods. This allows pet toy manufacturers to create unique and engaging products that will appeal to pet owners and their furry friends.

Another advantage of plastic injection molding is the speed at which products can be produced. Once the mold is created, the injection molding process can be automated, allowing for high-volume production with minimal human intervention. This means that pet toy manufacturers can quickly scale up their production to meet demand, ensuring that their products are readily available to consumers.

In addition to speed and precision, plastic injection molding offers cost savings for pet toy manufacturers. The initial investment in creating the mold may be higher than other manufacturing methods, but once the mold is in place, the cost per unit decreases significantly. This makes plastic injection molding a cost-effective option for producing large quantities of pet toys, allowing manufacturers to maximize their profits while keeping prices competitive for consumers.

Furthermore, plastic injection molding is a versatile process that can accommodate a wide range of materials, colors, and finishes. This flexibility allows pet toy manufacturers to experiment with different materials to find the best fit for their products. Whether they are looking for a durable material that can withstand rough play or a soft material that is gentle on pets’ teeth and gums, plastic injection molding can deliver the desired results.

The durability of products produced through plastic injection molding is another key benefit for pet toy manufacturers. The process creates strong and resilient products that can withstand the wear and tear of everyday use by pets. This durability not only ensures that the toys will last longer, but also provides peace of mind to pet owners who want to provide safe and long-lasting toys for their furry companions.

In conclusion, plastic injection molding offers numerous benefits for pet toy manufacturers looking to produce high-quality products efficiently and cost-effectively. From the ability to create complex shapes and designs to the speed and cost savings of high-volume production, this manufacturing process is a valuable tool for pet toy manufacturers. With its versatility, durability, and precision, plastic injection molding is a smart choice for producing pet toys that will delight pets and their owners alike.

How to Choose the Right Plastic Material for Injection Molding Pet Products

Plastic injection molding is a popular manufacturing process used to create a wide range of products, including pet products. When it comes to choosing the right plastic material for injection molding pet products, there are several factors to consider. In this article, we will discuss the different types of plastic materials commonly used in injection molding for pet products and provide tips on how to select the best material for your specific needs.

One of the most important factors to consider when choosing a plastic material for injection molding pet products is the durability of the material. Pets can be rough on their toys and accessories, so it is essential to select a material that can withstand wear and tear. Some of the most durable plastic materials commonly used in injection molding for pet products include polyethylene, polypropylene, and ABS. These materials are known for their strength and impact resistance, making them ideal for products that will be subjected to rough handling.

Another important factor to consider when choosing a plastic material for injection molding pet products is the safety of the material. Pets often chew on their toys and accessories, so it is crucial to select a material that is non-toxic and safe for pets to ingest. Materials such as polyethylene and polypropylene are considered safe for use in pet products, as they are non-toxic and do not contain harmful chemicals. It is essential to check the safety specifications of the plastic material you choose to ensure that it meets the necessary safety standards for pet products.

In addition to durability and safety, it is also essential to consider the flexibility and moldability of the plastic material when choosing a material for injection molding pet products. Some pet products, such as toys and accessories, may require a certain level of flexibility to accommodate different shapes and sizes. Materials such as polyethylene and polypropylene are known for their flexibility and moldability, making them ideal for products that require intricate designs and shapes.

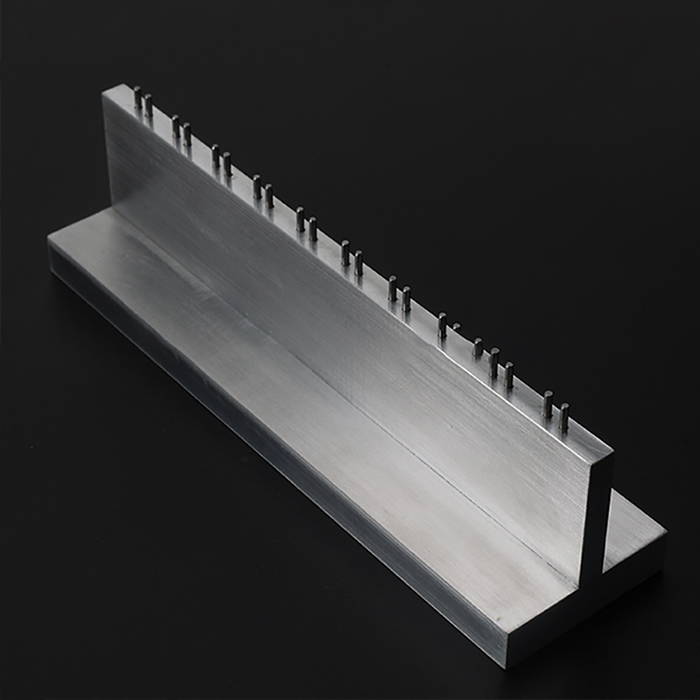

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

When selecting a plastic material for injection molding pet products, it is also important to consider the cost of the material. Different plastic materials vary in price, so it is essential to choose a material that fits within your budget while still meeting your quality and safety requirements. It is also important to consider the production volume of your pet products, as some materials may be more cost-effective for large production runs, while others may be more suitable for smaller quantities.

In conclusion, choosing the right plastic material for injection molding pet products is essential to ensure the durability, safety, flexibility, and cost-effectiveness of your products. By considering factors such as durability, safety, flexibility, moldability, and cost, you can select the best material for your specific needs. Whether you are manufacturing pet toys, accessories, or other products, selecting the right plastic material is crucial to the success of your injection molding project. By following these tips and guidelines, you can choose the best plastic material for your pet products and create high-quality, safe, and durable products for your furry friends.