Benefits of Plastic Injection Molding and Assembly

Plastic injection molding and assembly are essential processes in the manufacturing industry. These processes offer a wide range of benefits that make them popular choices for producing a variety of plastic products. From cost-effectiveness to efficiency and precision, plastic injection molding and assembly have revolutionized the way products are manufactured.

One of the key benefits of plastic injection molding is its cost-effectiveness. The process allows for high-volume production at a relatively low cost per unit. This is because the molds used in injection molding can be reused multiple times, reducing the overall cost of production. Additionally, the automation of the process helps to minimize labor costs, making it a cost-effective option for manufacturers.

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

| Surface finish | Polishing Finish / Slik Print / Texture Finish / Rubber Painting / Glossy Finish / Painting / Slik-Screen / Pad Print / EMI Coating / Electronic Plating / Laser Marking / Etc. |

Another advantage of plastic injection molding is its efficiency. The process is highly automated, which means that production can be carried out quickly and consistently. This results in faster turnaround times and increased productivity. Additionally, the high precision of injection molding ensures that each product is manufactured to exact specifications, reducing the likelihood of defects or errors.

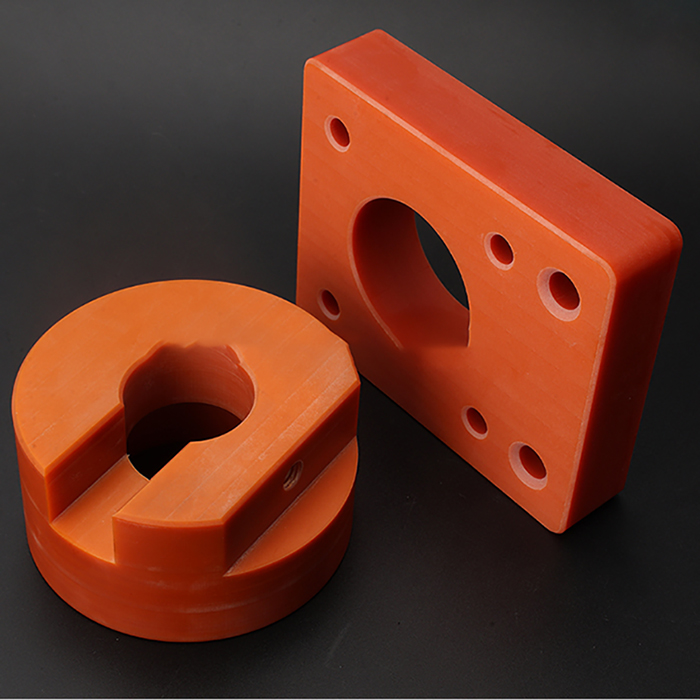

In addition to cost-effectiveness and efficiency, plastic injection molding and assembly offer a high level of precision. The molds used in injection molding are designed to produce products with tight tolerances and intricate details. This level of precision is essential for industries that require products to meet strict quality standards, such as the medical or aerospace industries.

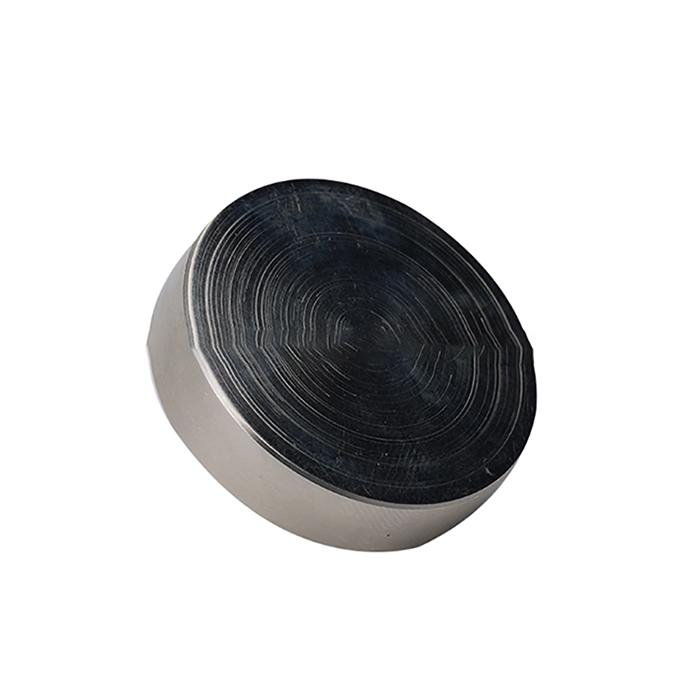

Furthermore, plastic injection molding and assembly are versatile processes that can be used to produce a wide range of products. From small, intricate components to large, complex parts, injection molding can accommodate a variety of shapes and sizes. This versatility makes it a popular choice for manufacturers in a range of industries.

One of the key advantages of plastic injection molding and assembly is the ability to produce products with a high level of consistency. The automated nature of the process ensures that each product is manufactured to the same high standard, reducing the likelihood of variations in quality. This consistency is essential for industries that require products to meet strict specifications and standards.

Moreover, plastic injection molding and assembly offer the advantage of being able to produce products with a wide range of materials. From thermoplastics to thermosets, injection molding can accommodate a variety of materials, allowing manufacturers to choose the best material for their specific application. This flexibility makes injection molding a versatile option for a range of industries.

In conclusion, plastic injection molding and assembly offer a wide range of benefits that make them popular choices for manufacturers. From cost-effectiveness and efficiency to precision and versatility, these processes have revolutionized the way products are manufactured. With the ability to produce products with a high level of consistency and a wide range of materials, plastic injection molding and assembly are essential processes in the manufacturing industry.