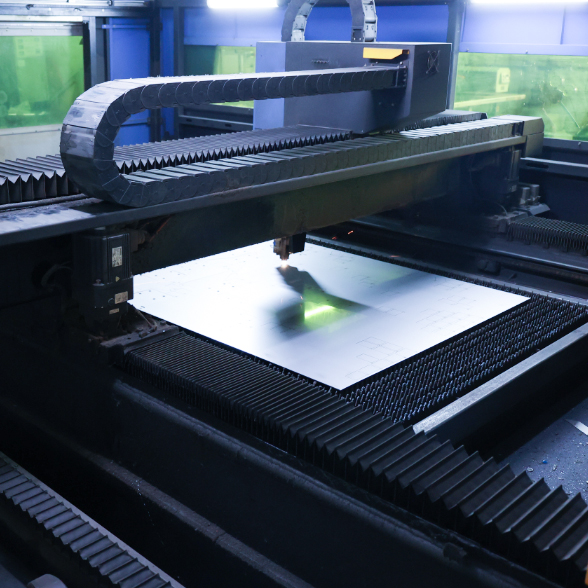

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that involves transforming flat metal sheets into various shapes and components. It encompasses a range of techniques, including cutting, bending, welding, and finishing, to create finished products from sheet metal. Sheet metal fabrication is widely used in industries such as construction, automotive, aerospace, electronics, and manufacturing to create a wide range of products, including enclosures, panels, frames, brackets, and more.

Our company specializes in delivering comprehensive and top-notch sheet metal fabrication solutions to meet a wide range of customer needs.

Sheet Metal Materials Available

Available Sheet Metal Finishes

- Standard

- Bead Blast

- Anodize (Type II Or Type III)

- Chem Film (Chromate Conversion Coating)

- Powder Coat

- Electroless Nickel Plating

- Gold Plating

- Silver Plating

Sheet Metal Applications

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

- Electrical enclosure

- Parts for computer electronics

- Chassis

- Brackets

- Cabinets

- Mounts

Advantages of Sheet Metal Fabrication

The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities.

- Low material waste

- Multiple finishing options

- Can cost-effectively scale to production volumes

Cases Of CNC Machining

Ready to Work On your Next Project?

Let us help you provide high quality parts in short time. Get your project started now!