Benefits of Using Plastic Dustbin Injection Molding Technology

Plastic dustbin injection molding technology has revolutionized the way plastic dustbins are manufactured. This innovative process involves injecting molten plastic into a mold cavity, which then cools and solidifies to form the desired shape. The result is a high-quality, durable plastic dustbin that is both cost-effective and efficient to produce.

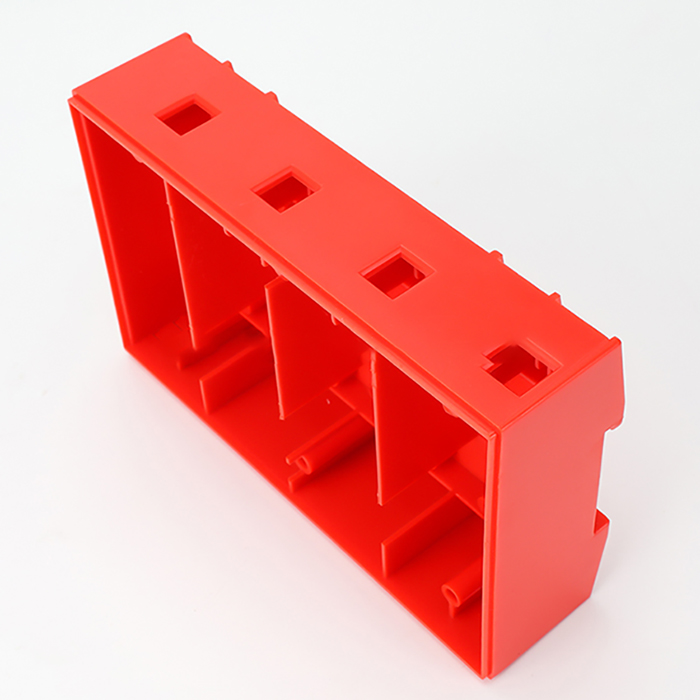

One of the key benefits of using plastic dustbin injection molding technology is the ability to create complex shapes and designs with precision and accuracy. This means that manufacturers can produce dustbins in a wide range of sizes, styles, and colors to meet the specific needs and preferences of their customers. Whether it’s a small, compact dustbin for a bathroom or a large, industrial-sized bin for a commercial setting, injection molding technology can deliver the perfect solution.

Another advantage of plastic dustbin injection molding is the speed and efficiency of the manufacturing process. With traditional methods, such as blow molding or rotational molding, it can take days or even weeks to produce a single dustbin. In contrast, injection molding allows for rapid production cycles, with each mold capable of producing hundreds or even thousands of dustbins in a matter of hours. This not only reduces production costs but also ensures a quick turnaround time for customers.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Our Services | OEM/ODM |

Furthermore, plastic dustbin injection molding technology offers superior quality and consistency compared to other manufacturing methods. The precise control over the injection process ensures that each dustbin is produced to the exact specifications, with consistent wall thickness, smooth surfaces, and sharp details. This level of quality is essential for ensuring the durability and longevity of the dustbins, especially in high-traffic or outdoor environments where they may be subjected to rough handling or extreme weather conditions.

In addition to quality and efficiency, plastic dustbin injection molding technology also offers environmental benefits. The process generates minimal waste, as any excess plastic can be recycled and reused in future production runs. This not only reduces the environmental impact of manufacturing but also helps to conserve natural resources and reduce overall carbon emissions. Furthermore, plastic dustbins themselves are highly recyclable, making them a sustainable choice for waste management solutions.

Overall, plastic dustbin injection molding technology offers a wide range of benefits for manufacturers, customers, and the environment. From the ability to create complex designs with precision and speed to the superior quality and consistency of the finished products, injection molding technology is a game-changer in the world of plastic dustbin manufacturing. By embracing this innovative technology, manufacturers can streamline their production processes, reduce costs, and deliver high-quality, sustainable products to their customers.