Table of Contents

Benefits of Using Plastic Molding Injection Products for Concrete Molds

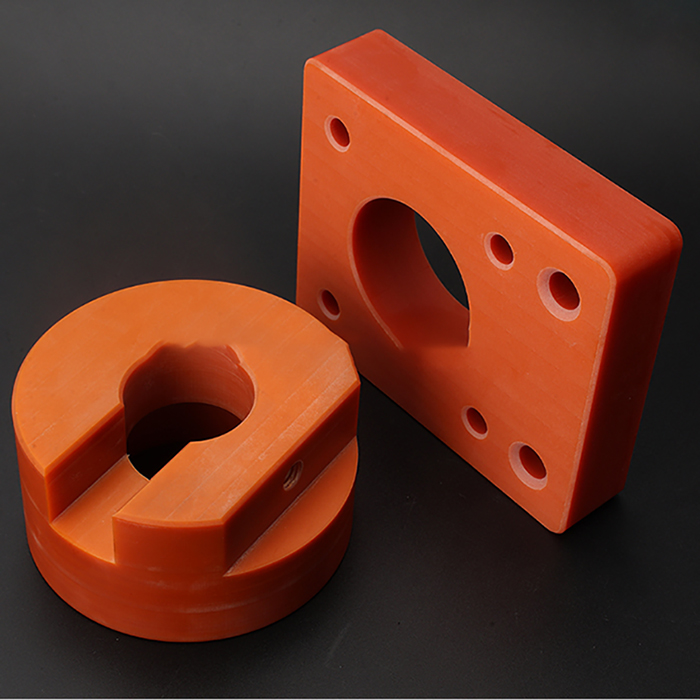

Plastic molding injection products have become increasingly popular in the manufacturing industry, particularly in the production of concrete molds. These products offer a wide range of benefits that make them a preferred choice for many manufacturers. In this article, we will explore some of the key advantages of using plastic molding injection products for concrete molds.

One of the primary benefits of using plastic molding injection products for concrete molds is their durability. Plastic molding injection products are made from high-quality materials that are designed to withstand the rigors of the manufacturing process. This means that they are less likely to break or wear out over time, resulting in a longer lifespan for the concrete molds. This durability can help manufacturers save money in the long run by reducing the need for frequent replacements.

In addition to their durability, plastic molding injection products are also highly customizable. Manufacturers can easily create molds in a wide range of shapes and sizes to meet their specific needs. This flexibility allows for greater creativity in the design and production of concrete molds, resulting in products that are more unique and innovative. Customization also allows manufacturers to create molds that are tailored to their specific production processes, resulting in more efficient and effective manufacturing operations.

Another key benefit of using plastic molding injection products for concrete molds is their cost-effectiveness. Plastic molding injection products are typically more affordable than other types of mold-making materials, such as metal or wood. This can help manufacturers save money on production costs, allowing them to invest more in other areas of their business. Additionally, the efficiency of plastic molding injection products can help manufacturers reduce waste and improve overall production processes, further contributing to cost savings.

Plastic molding injection products are also lightweight and easy to handle, making them ideal for use in a variety of manufacturing settings. Their lightweight nature makes them easy to transport and maneuver, allowing for greater flexibility in the production process. This can help manufacturers streamline their operations and improve overall efficiency. Additionally, the ease of handling plastic molding injection products can help reduce the risk of injury to workers, creating a safer working environment.

Furthermore, plastic molding injection products are environmentally friendly. Many plastic molding injection products are made from recyclable materials, making them a sustainable choice for manufacturers. By using these products, manufacturers can reduce their environmental impact and contribute to a more sustainable future. Additionally, the efficiency of plastic molding injection products can help manufacturers reduce energy consumption and waste, further minimizing their environmental footprint.

In conclusion, plastic molding injection products offer a wide range of benefits for manufacturers producing concrete molds. From their durability and customization options to their cost-effectiveness and environmental friendliness, plastic molding injection products are a versatile and efficient choice for manufacturers looking to improve their production processes. By utilizing plastic molding injection products, manufacturers can create high-quality concrete molds that meet their specific needs while also reducing costs and environmental impact.

How to Choose the Right Plastic Molding Injection Products for Concrete Molds

Plastic molding injection products are essential components in the creation of concrete molds. These products play a crucial role in shaping and forming concrete into various structures and designs. Choosing the right plastic molding injection products for concrete molds is a critical decision that can impact the quality and durability of the final product. In this article, we will discuss some key factors to consider when selecting plastic molding injection products for concrete molds.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Packing | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

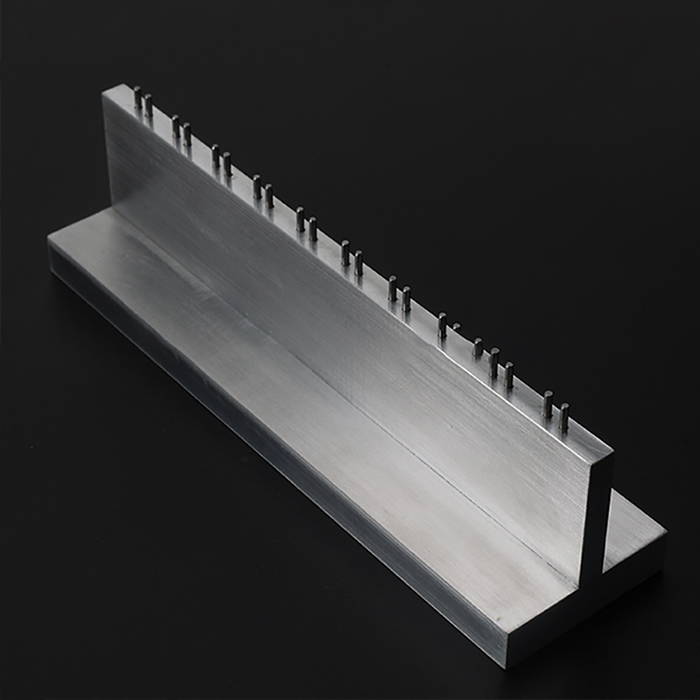

One of the most important factors to consider when choosing plastic molding injection products for concrete molds is the material used in the manufacturing process. Different materials have varying levels of durability, flexibility, and heat resistance, which can affect the overall quality of the concrete mold. It is essential to select a material that can withstand the high temperatures and pressures involved in the injection molding process.

Another crucial factor to consider is the design and shape of the plastic molding injection products. The design of the products will determine how well they can mold and shape the concrete. It is important to choose products that have a smooth and uniform surface to ensure that the concrete mold is formed correctly. Additionally, the shape of the products should be compatible with the desired shape and size of the concrete mold.

Furthermore, it is important to consider the size and dimensions of the plastic molding injection products. The size of the products should be appropriate for the size of the concrete mold being created. Choosing products that are too small or too large can result in an uneven or poorly formed concrete mold. It is essential to carefully measure and select products that are the right size for the project at hand.

In addition to size and material, it is also important to consider the quality and reputation of the manufacturer of the plastic molding injection products. Working with a reputable and experienced manufacturer can ensure that the products are of high quality and meet industry standards. It is important to research and choose a manufacturer that has a proven track record of producing reliable and durable plastic molding injection products.

When selecting plastic molding injection products for concrete molds, it is also important to consider the cost and budget of the project. It is essential to balance quality and affordability when choosing products to ensure that the final product meets the desired specifications without exceeding the budget. It is important to compare prices and quality from different manufacturers to find the best value for the project.

In conclusion, choosing the right plastic molding injection products for concrete molds is a critical decision that can impact the quality and durability of the final product. It is important to consider factors such as material, design, size, manufacturer reputation, and cost when selecting products. By carefully evaluating these factors and making informed decisions, you can ensure that your concrete molds are of the highest quality and meet your project requirements.