Key Factors to Consider for Ensuring Quality Control in Plastic Injection Molding

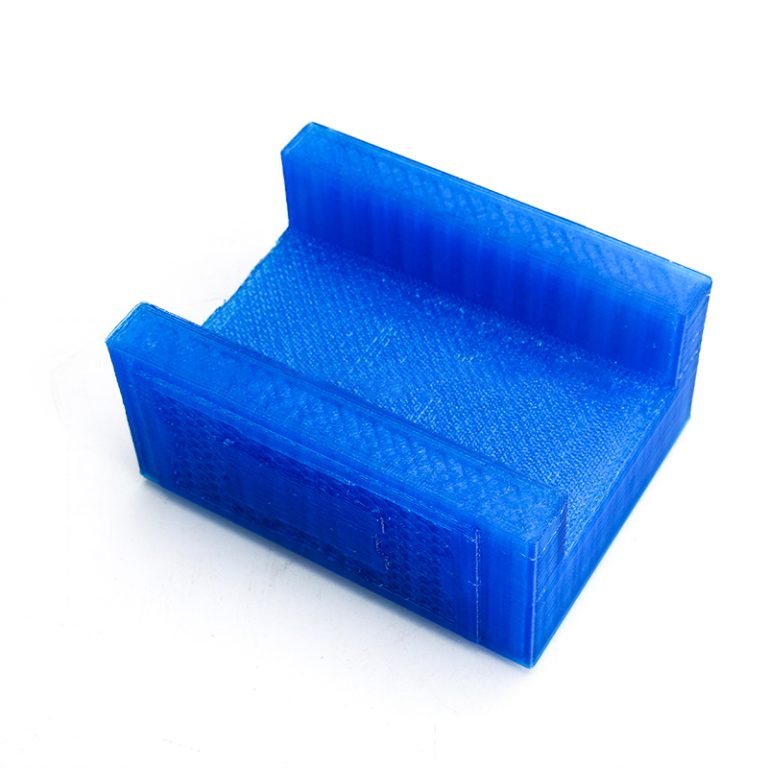

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. This process allows for the production of a wide range of plastic products, from small components to large parts. However, ensuring quality control in plastic injection molding is crucial to producing high-quality products that meet the required specifications.

One of the key factors to consider for ensuring quality control in plastic injection molding is the selection of the right materials. The quality of the raw materials used in the injection molding process can have a significant impact on the final product. It is essential to work with reputable suppliers who provide high-quality materials that meet the required specifications. Using substandard materials can result in defects in the final product, leading to increased scrap rates and production costs.

Another important factor to consider for quality control in plastic injection molding is the design of the mold. The design of the mold plays a crucial role in determining the quality of the final product. It is essential to work with experienced mold designers who can create molds that meet the required specifications and produce high-quality parts. Poorly designed molds can result in defects such as warping, sink marks, and flash, which can affect the overall quality of the product.

In addition to material selection and mold design, process control is another key factor to consider for quality control in plastic injection molding. The injection molding process involves several variables, such as temperature, pressure, and injection speed, that can affect the quality of the final product. It is essential to monitor and control these variables to ensure that the parts are produced consistently and meet the required specifications. Implementing process control measures, such as regular monitoring and adjustment of process parameters, can help to minimize variations in the production process and improve product quality.

Quality control in plastic injection molding also involves inspecting and testing the parts to ensure that they meet the required specifications. Inspection and testing can help to identify defects and deviations from the desired quality standards, allowing for corrective actions to be taken before the parts are shipped to customers. It is essential to implement a robust inspection and testing process that includes visual inspection, dimensional measurement, and functional testing to ensure that the parts meet the required quality standards.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

Furthermore, maintaining a clean and well-maintained production environment is essential for quality control in plastic injection molding. Contaminants such as dust, dirt, and grease can affect the quality of the final product and lead to defects. It is essential to implement regular cleaning and maintenance procedures to keep the production environment clean and free of contaminants. Additionally, implementing proper storage and handling procedures for raw materials and finished parts can help to prevent contamination and ensure product quality.

In conclusion, quality control is a critical aspect of plastic injection molding that can have a significant impact on the quality of the final product. By considering factors such as material selection, mold design, process control, inspection and testing, and production environment cleanliness, manufacturers can ensure that their products meet the required specifications and quality standards. Implementing robust quality control measures can help to minimize defects, reduce scrap rates, and improve overall product quality.