If you’re looking for CNC machined aluminum parts for sale or a manufacturer that specializes in producing such parts, here are some key points to consider:

CNC Machined Aluminum Parts:

1.Applications:

2.Automotive: Engine components, brackets, panels.

3.Aerospace: Structural components, housings, brackets.

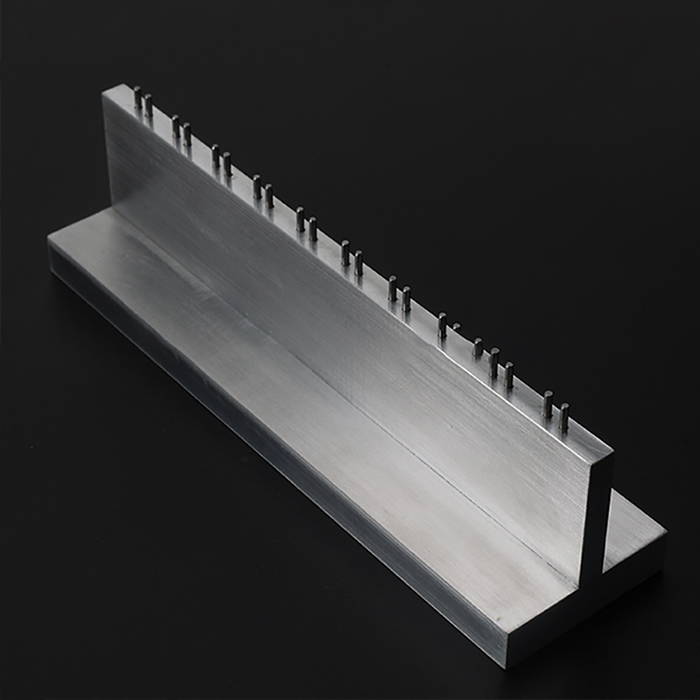

4.Electronics: Enclosures, heatsinks, connectors.

5.Industrial Equipment: Machine parts, tooling components.

6.Consumer Goods: Handles, knobs, frames.

7.Benefits:

8.Precision: CNC machining offers high accuracy and repeatability.

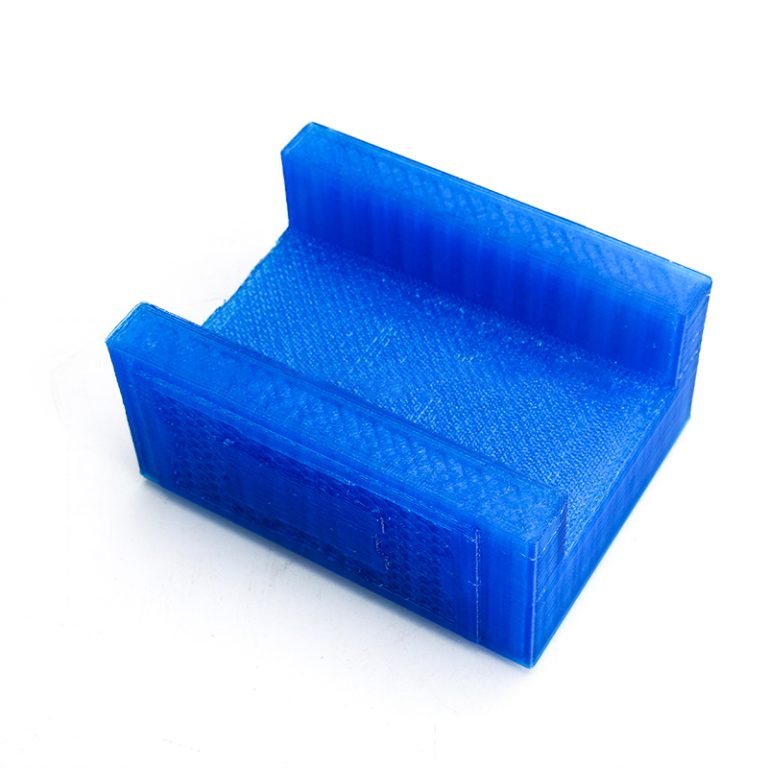

9.Versatility: Can produce complex geometries and intricate designs.

10.Strength-to-Weight Ratio: Aluminum is lightweight yet strong.

11.Corrosion Resistance: Suitable for various environments.

12.Manufacturer Considerations:

13.Expertise: Look for manufacturers with experience in CNC machining aluminum.

14.Capabilities: Assess their ability to handle your specific part requirements in terms of size, complexity, and volume.

15.Quality Control: Ensure they follow stringent quality standards and have certifications if required.

16.Materials: Familiarity with different grades of aluminum and their applications.

17.Services Offered:

18.Design Assistance: Some manufacturers provide design feedback and optimization.

19.Prototyping: Rapid prototyping services to test designs before full-scale production.

20.Finishing Options: Surface finishes like anodizing, polishing, or powder coating.

21.Assembly: Ability to assemble components if needed.

Finding Manufacturers:

22.Online Directories: Websites like ThomasNet, Alibaba, or specialized CNC machining directories can list manufacturers.

23.Trade Shows: Attending manufacturing trade shows can connect you with reputable suppliers.

24.Referrals: Ask within your industry or professional network for recommendations.

25.RFQ (Request for Quote): Contact multiple manufacturers for quotes and compare their capabilities and pricing.

Conclusion:

Whether you’re sourcing CNC machined aluminum parts for specific applications or looking to partner with a manufacturer for ongoing production needs, thorough research into capabilities, quality standards, and customer reviews will help you find the right supplier. Be clear about your requirements and communicate openly to ensure expectations are met regarding quality, timeline, and cost.