CNC machining refers to the process of using computer numerical control (CNC) machines to manufacture mechanical parts with high precision and consistency. These parts can vary widely in complexity and application, but some common CNC-machined mechanical parts include:

1.Prototypes and Production Parts: CNC machines are used to produce both prototypes for testing and final production parts. This includes components for industries such as automotive, aerospace, medical devices, and consumer electronics.

2.Tooling Components: CNC machining is essential for producing molds, dies, and fixtures used in manufacturing processes. These components ensure consistent production quality and efficiency.

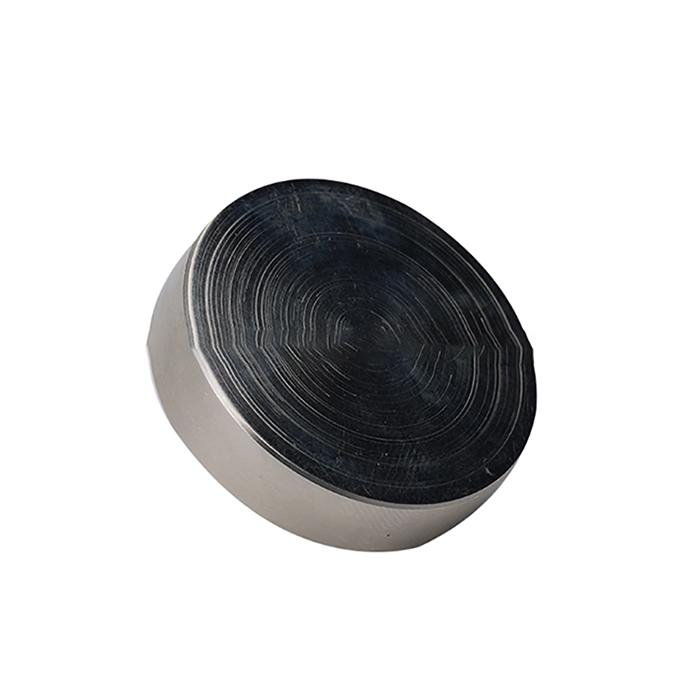

3.Precision Components: Many mechanical assemblies require precision parts that can only be reliably produced with CNC machining. Examples include gears, shafts, bearings, and housings.

4.Customized Parts: CNC machines can quickly and accurately produce customized parts according to specific designs and requirements. This flexibility is valuable in industries where unique or specialized components are needed.

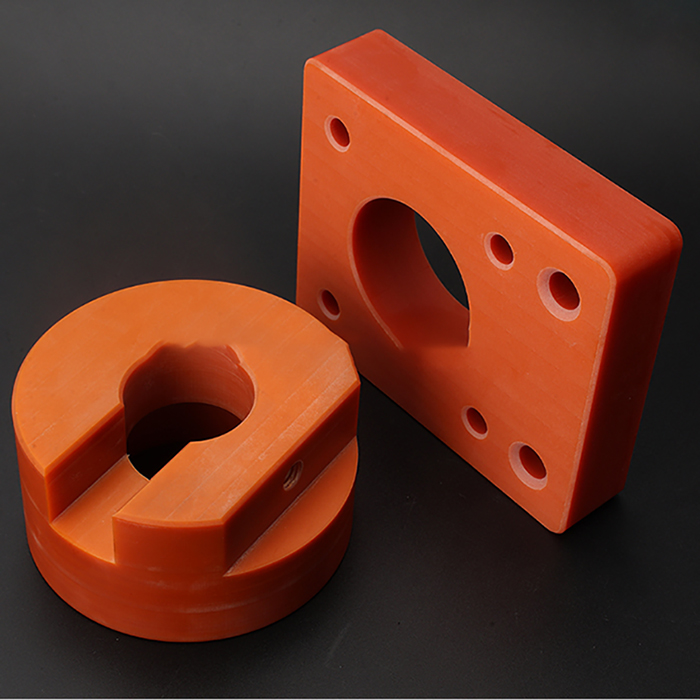

5.Complex Shapes: CNC machining can handle complex geometries that are difficult or impossible to achieve with conventional machining methods. This includes intricate designs with tight tolerances and fine surface finishes.

6.Materials Diversity: CNC machining can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics (acrylic, nylon, PEEK), and composites. This versatility makes it suitable for various applications and industries.

7.Sub-Assemblies: CNC machining is often used to produce sub-assemblies of larger mechanical systems. These sub-assemblies can be tested independently before final integration, ensuring overall system reliability and performance.

When looking for CNC machining services for mechanical parts, it’s important to consider the capabilities of the CNC machine shop, their experience with similar projects, the quality assurance processes they have in place, and their ability to meet specific design and production requirements. This ensures that the parts produced meet the desired specifications and performance criteria.